Have you suffered from the costly

quality complaint in global purchasing?

There are thousands of companies offering

quality check in the market. They offer very nice price for their service. But

they may not understand your product or know your production technic. And you

get a report full of pictures from the spot check goods. Is this kind of

superficial report on the selected samples what you like?

We are different! We know your product. We

don’t just look to the superficial problem, but we involve ourselves

into the production procedure, technic, product engineering and supplier

shortcomings. We give proposal of economic solutions. Only in this way we can

secure stable quality in whole batch of production and deliver in

future continuously improving quality.

It would be nice when you involve us as

early as possible. With our whole service package you get benefit of less

quality risk and reduction of costly complaint during international purchasing.

A systematic inspection may be carried out on different

phase as below, which helps on-time corrective action before

finishing complete production:

1. Pre-Production

Inspection

2.

Trial-production Article Inspection

3. During

Production Inspection

4. Final

Pre-shipment Inspection

5. Container

Loading Supervision

Checklist of

inspection:

1. Product

specification check

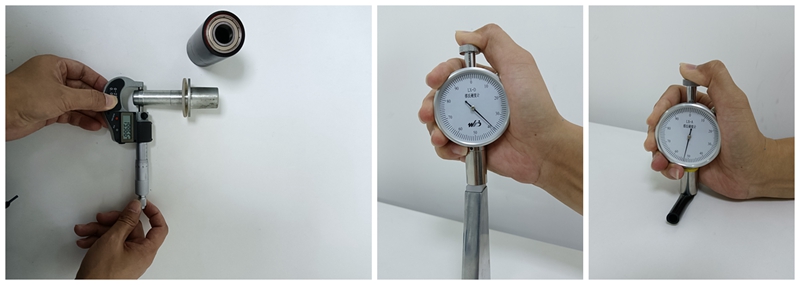

2. Material

3. Measurements

check

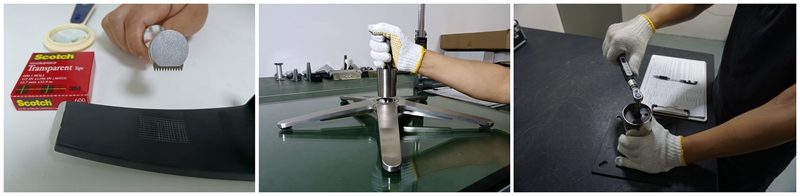

4. Aesthetic,

surface check

5. On-site

function check and testing

6. Quantity

verifying

7. Packaging

(carton or pallet) & Labels & markings check

8. Select

samples and send to third party if necessary

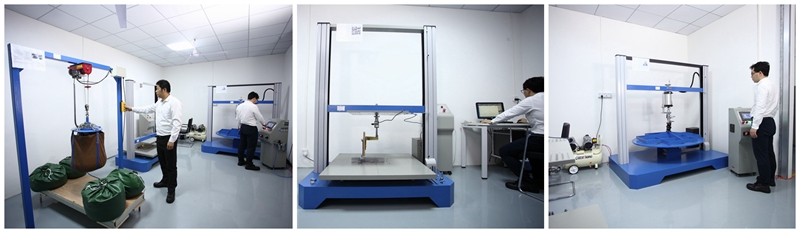

In house test if

necessary, test capability:

1. Vertical

static load test

2. Side static

load test

3. Impact

test

4. Rotation

cycle test

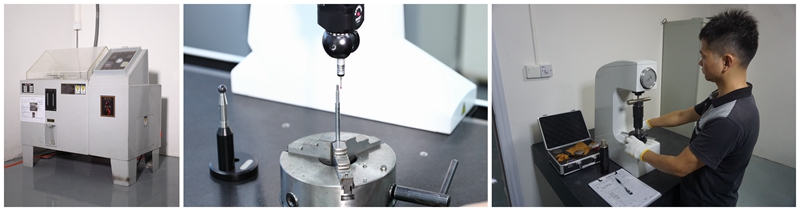

5. Corrosion

test

6. Packing

drop test

7. Glider

drag test

8. Powder

adhesion test

9. Hardness test